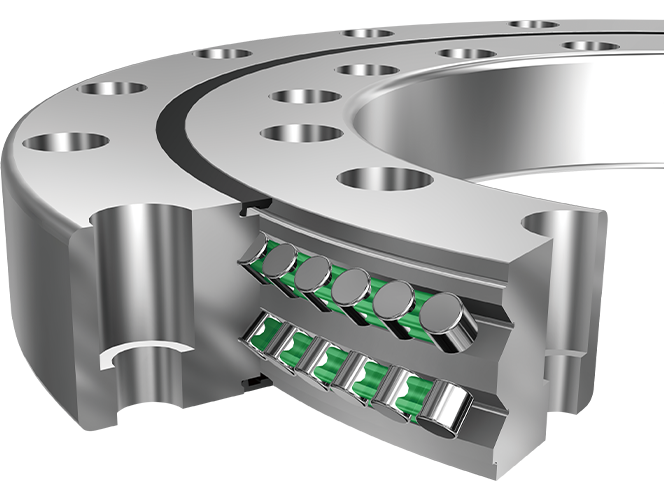

Double Row Angular Contact Ring

By adopting multiple rows of raceways and small-diameter rollers, the number of rollers is approximately five times that of the conventional Model RU cross-roller ring (for the RW228). Compactness is maintained and rigidity and precision are improved, while torque is reduced. The integrally structured inner and outer rings have mounting holes for directly fixing to the equipment.

Types

Highlight feature tags

- High rigidity

- Inner ring rotation

- Outer ring rotation

- Integrated inner / Outer ring type

- Large load capacity

- Rotation accuracy

- High rigidity

- Inner ring rotation

- Outer ring rotation

- Integrated inner / Outer ring type

- Large load capacity

- Rotation accuracy

- High rigidity

- Inner ring rotation

- Outer ring rotation

- Integrated inner / Outer ring type

- Large load capacity

- Rotation accuracy

Search products by various conditions

Features

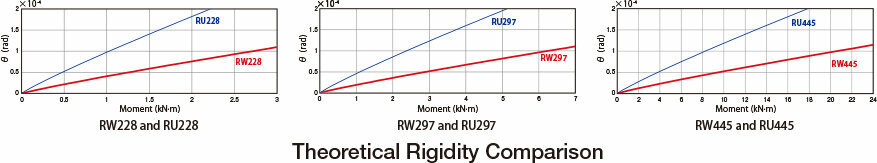

High Rigidity

An increased number of rollers achieves high rigidity.

The Model RW uses multiple raceways and small-diameter rollers to increase the overall roller quantity. This achieves much higher rigidity when compared to conventional THK cross roller rings with the same inner and outer dimensions.

High Accuracy

Wobbling accuracy of 2 μm allows for high rotational accuracy.

With the Model RW, it is possible to specify the runout accuracy (wobbling accuracy) of actual operating positions such as machining position and measurement position.

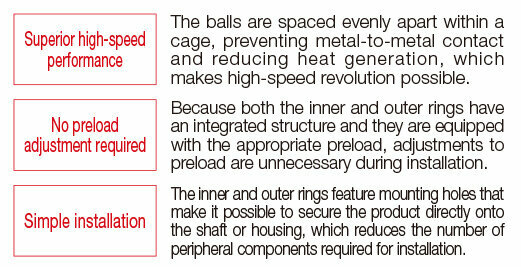

Easy to Install

Mounting holes in the inner and outer rings reduce the number of design steps and components.

The Model RW has mounting holes in the inner and outer rings, eliminating the need for other mounting components and allowing it to attach directly to shafts and housings.

Lineup

| Model No. | Inner diameter | Outer diameter |

| RW228 | 160 | 295 |

|---|---|---|

| RW297 | 210 | 380 |

| RW445 | 350 | 540 |

Available in dimensions other than those listed above. See p. 10 for details.

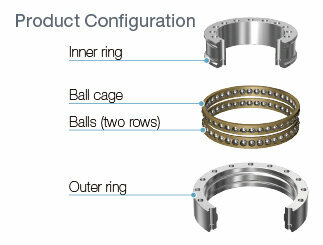

Structure and Features

The Model BWH is a bearing based on a cross-roller ring that adopts balls as the rolling elements. By arranging the balls in two rows, this configuration provides rigidity while also being suited to high-speed applications.

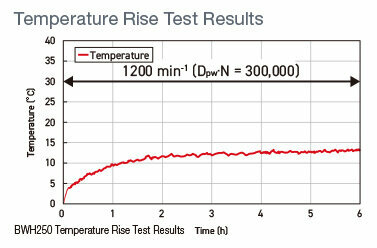

Temperature rose less than 15°C when rotating continuously at a Dpw・N value of 300,000. (Dpw N = ball pitch circle diameter x rotational speed)

- Note: The data is based on the use of dedicated grease in our testing equipment.

Results may vary based on the device structure or operating conditions.